Understanding Mullen Burst Test Equipment and Burst Test ASTM Standards for Accurate Fabric Strength Analysis

By PAGE Editor

Introduction

In the field of textile and packaging material testing, accurately assessing material strength is critical to ensuring product performance and durability. Among the most essential tests in this context is the bursting strength test. This test, often conducted with Mullen Burst Test Equipment, is widely adopted in quality control laboratories for testing paper, textiles, nonwovens, and packaging materials. The relevance of this test is underscored by the standardized guidelines defined in Burst Test ASTM Standards. In this article, we delve into the intricacies of bursting strength testing, explore the role of Mullen Burst Test Equipment, examine the applicable Burst Test ASTM Standard, and introduce the benefits of using a professional Lab Bursting Strength Tester.

1. What is a Bursting Strength Test?

A bursting strength test measures the ability of a material to withstand pressure before it ruptures. In practical terms, this test simulates the forces that materials such as paperboard, fabric, or corrugated fiberboard may face during use or handling. It is especially important in industries like textiles, packaging, and leather manufacturing, where durability is a core requirement.

Key Parameters Measured:

Maximum pressure sustained before rupture (expressed in kPa or psi)

Elastic properties under pressure. Uniformity of material strength across samples

2. The Mullen Burst Test Equipment: An Overview

Mullen Burst Test Equipment refers to the machinery used to apply hydraulic pressure to a sample until it bursts. Named after John Mullen, who developed the method in the early 1900s, this equipment remains a cornerstone in material testing.

Main Components:

Hydraulic system

Circular diaphragm (rubber membrane)

Clamping rings to secure the test specimen

Digital or analog pressure gauge

How It Works: The test sample is clamped between two plates. Hydraulic pressure is applied through the diaphragm, gradually increasing until the sample bursts. The pressure at rupture is recorded as the material's bursting strength.

Advantages of Mullen Burst Test Equipment:

Accurate and repeatable results

Applicable to a wide range of materials

Compact, lab-friendly design

3. Burst Test ASTM Standard: Ensuring Consistency and Reliability

To maintain consistency across industries, several ASTM (American Society for Testing and Materials) standards guide the bursting strength test.

Notable Burst Test ASTM Standards:

ASTM D3786: Standard Test Method for Hydraulic Bursting Strength of Textile Fabrics

—Diaphragm Bursting Strength Tester Method

ASTM D774: Standard Test Method for Bursting Strength of Paper

ASTM D751: Test Methods for Coated Fabrics (includes burst testing procedures)

These standards define:

Test procedures and equipment calibration

Sample preparation methods

Acceptable result tolerances

Benefits of Adhering to ASTM Standards:

Global credibility and acceptance

Reliable benchmarking

Consistent data for quality assurance

4. Applications of Bursting Strength Testing Across Industries

Bursting strength testing is utilized across various sectors to ensure product reliability.

Industries and Use Cases:

Textile Industry: Testing fabrics for durability in garments, upholstery, and industrial textiles

Packaging: Measuring the resistance of paper and corrugated board used in shipping

Medical Textiles: Assessing nonwovens in surgical gowns and drapes

Automotive: Validating fabric strength in car interiors

Each application demands accurate and repeatable testing to meet regulatory and consumer expectations.

5. Why Choose a Professional Lab Bursting Strength Tester

When precision, reliability, and compliance are non-negotiable, investing in a dedicated Lab Bursting Strength Tester is the optimal solution.

Key Features of Modern Lab Bursting Strength Testers:

Digital pressure sensors for accurate data capture

Automated sample clamping

Touchscreen interfaces with data storage and export

Compliance with ASTM, ISO, and other international standards

Advantages:

Saves time through automation

Reduces human error

Facilitates traceability with data logging

Improves quality assurance processes

For example, some of the latest models come with embedded software that automatically calibrates the equipment, provides real-time graphical data, and exports reports in formats compatible with LIMS (Laboratory Information Management Systems).

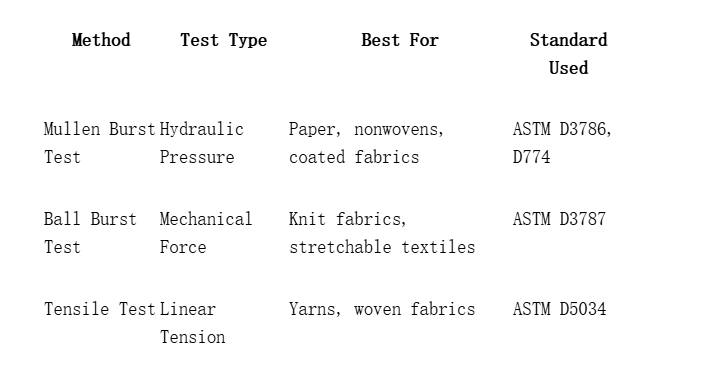

6. Comparison: Mullen Burst Test Equipment vs. Other Methods

While Mullen Burst Test Equipment is widely used, other methods like ball burst testing (ASTM D3787) or tensile testing may be considered in certain scenarios. However, the Mullen method is preferred for:

Materials with multi-directional fiber orientation

Nonwovens or irregular textiles

Packaging materials where puncture and rupture resistance are critical

Comparison Table:

7. Key Considerations When Selecting Mullen Burst Test Equipment

Choosing the right equipment requires evaluating several factors:

Compliance: Ensure it meets relevant Burst Test ASTM Standard (e.g., ASTM D3786)

Accuracy and Repeatability: Look for high-precision digital sensors

Ease of Use: Features like touchscreen interfaces and automatic clamping

Data Handling: Built-in memory, USB/export options, software integration

After-Sales Support: Availability of training, maintenance, and calibration services

A well-selected Lab Bursting Strength Tester enhances operational efficiency and ensures consistent quality in manufacturing and R&D environments.

Conclusion

In conclusion, bursting strength testing plays a pivotal role in ensuring the reliability and durability of a wide array of materials. Mullen Burst Test Equipment, backed by established Burst Test ASTM Standards, provides an industry-proven solution for consistent and accurate results. Whether in textiles, packaging, or technical fabrics, a robust Lab Bursting Strength Tester enhances quality control and ensures compliance with global standards. For manufacturers and laboratories committed to excellence, investing in the right bursting strength tester is not just a technical decision but a strategic imperative.

Optimize your material testing today with advanced Mullen Burst Test Equipment and ensure your products meet every Burst Test ASTM Standard with confidence.

For more information on textile testing methods/standards

or textile testing machines, contact us:

What's App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: sales@tes.hk

HOW DO YOU FEEL ABOUT FASHION?

COMMENT OR TAKE OUR PAGE READER SURVEY

Featured

Your website is often the first thing a potential client sees.